Case Study

Revolutionizing Server Thermal Management for a Dell OEM

Challenge

In the race to deliver compact, high-performance servers, a Dell OEM came to us with a challenge that had stymied others: managing the intense heat and airflow complications inherent in high-density server configurations.

Addressing Thermal and Performance Risks in High-Density Server Design

Modern high-density racks pack powerful CPUs, GPUs, and other components into much smaller spaces, drastically increasing thermal output. While traditional data centers were designed for about 5–10 kW per rack, today’s high-performance environments often exceed 30 kW, with hyperscale deployments reaching 50 kW or more. This surge in heat generation poses a significant challenge for conventional cooling methods.

The tight physical arrangement of components restricts airflow, leading to “hotspots”—localized areas of excessive heat that can cause critical components, such as GPUs, to overheat and malfunction. Traditional air-cooling strategies, such as hot aisle/cold aisle containment or raised floor with perforated tiles, often fall short in these environments. The volume of air required to cool such racks frequently exceeds the capacity of standard HVAC systems, causing uneven airflow and thermal inconsistencies.

These thermal constraints directly impact server performance and reliability. Without adequate cooling, servers risk thermal throttling, reducing processing power to avoid overheating. Prolonged exposure to high temperatures also damages hardware, increasing the likelihood of data loss, downtime, and costly replacements.

Furthermore, the energy consumption of cooling systems rises dramatically in these scenarios—accounting for up to 30–40% of a data center’s total energy use. This not only drives up operational costs but also introduces sustainability concerns, especially where traditional cooling relies on high water or energy usage.

Solving this challenge required a comprehensive, rack-level thermal strategy that could maintain performance, improve reliability, and reduce both energy consumption and long-term costs.

Services Rendered

Research and Development

User interviews (ie. comprehensive personas)

Process mapping (ie. end to end user journeys)

User-driven product requirements

Competitor product analysis

Design and Creation

Prototyping Software (low fidelity) (eg. Balsamiq)

Hand-drawn industrial designs

Photoshop renderings (ie. customer feedback)

Solidworks with PLM (ie. Complete rendering and creation)

Software Development

Platform Architecture (eg. AWS loT)

Application Development (eg. React, Python, Cognito)

Embedded Linux (eg. device operation)

Automated Testing and Build (eg. Github Actions)

Project Management

Modified Agile Hardware Design (MAHD)

JIRA CMMI for internal work tracking

Harvest Integration for project budgeting and oversight

Solution: Advanced CFD-Driven Micro-Fluidics and Modular Design for Optimized Cooling

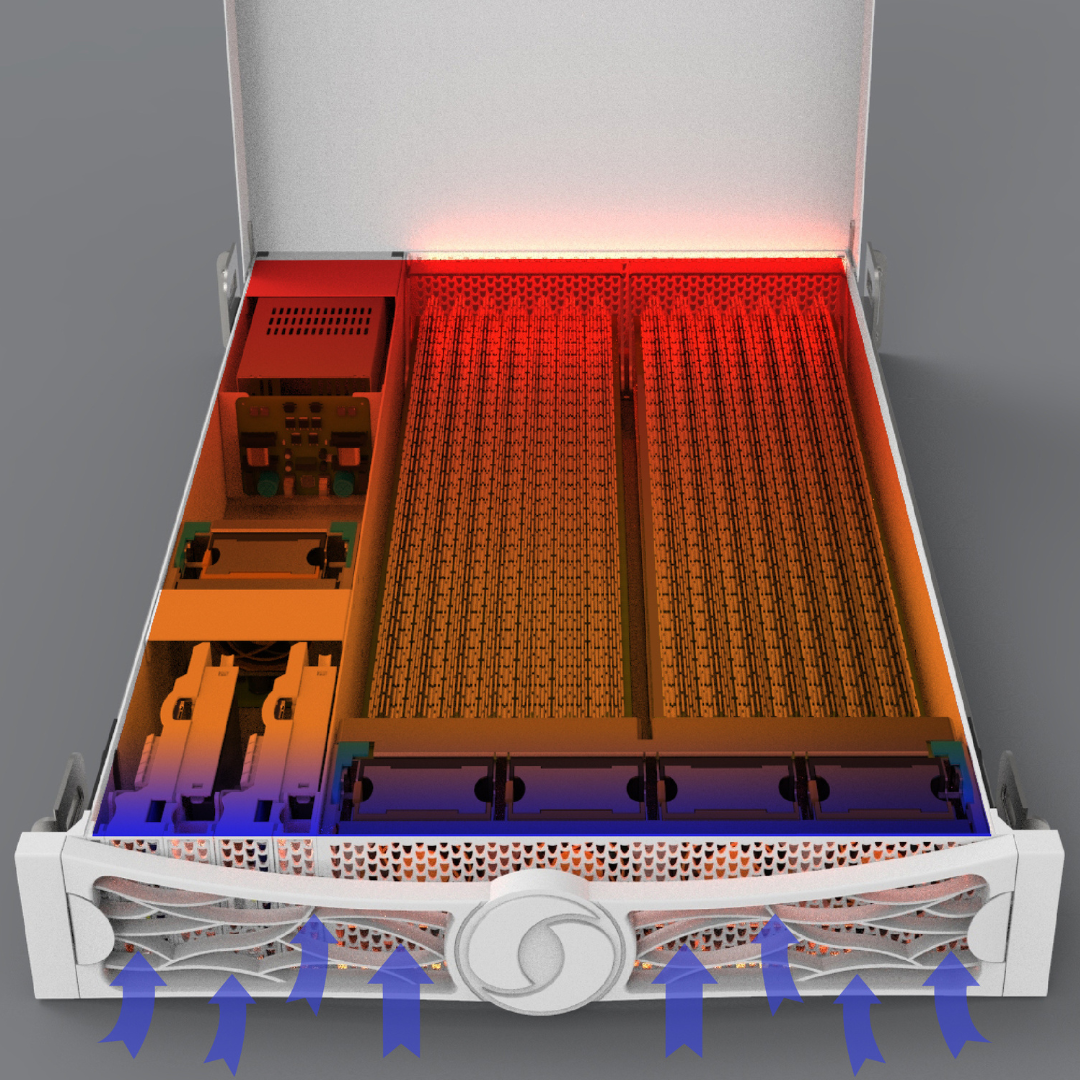

To tackle the problem, we adopted a full-rack CFD modeling approach. Instead of focusing solely on individual server units, we analyzed the layout of the entire rack—mapping out how thermal energy traveled between adjacent metal enclosures. This gave us a detailed understanding of how internal heat sources interacted and influenced surrounding systems.

We built a geometric representation of the entire server rack, chips, heatsinks, and the air volume around them. We defined critical boundary conditions: chip-level heat generation, inlet air temperatures and flow rates, and ambient thermal conditions. Running these simulations with CFD solvers allowed us to visualize airflow and temperature gradients across the entire rack.

Python played a key role throughout the process:

Automation of simulations via integration with commercial CFD software (e.g., Ansys Fluent through PyFluent)

Post-processing and visualization of airflow streamlines and temperature maps

Design optimization for heatsinks and cooling strategies through batch simulation and data analysis

From this data, we identified zones of thermal shadowing, where airflow was restricted and temperatures spiked due to cumulative heating from upstream servers. These insights enabled us to design and implement proprietary micro-fluidics heatsink technology that precisely directed and distributed airflow across each fin, improving cooling performance at the component level.

We collaborated with a local EDM (Electrical Discharge Machining) shop to produce these fin designs using high-grade aluminum, ensuring they were scalable and manufacturable at production quality.

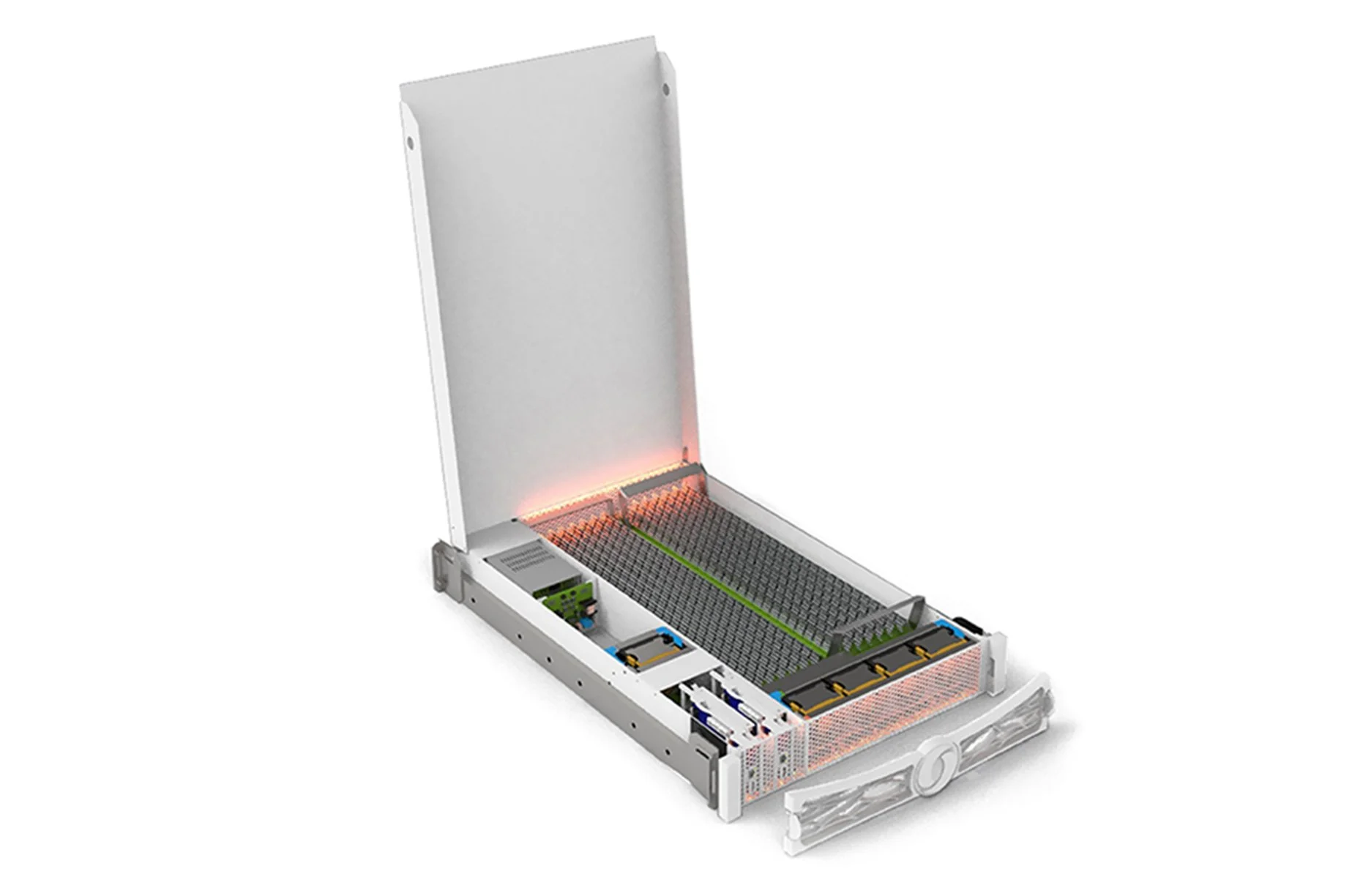

To support the needs of field teams and future scalability, we leveraged our expertise in custom enclosures to design modular "pull and place" boards. This allowed for top-down configurability and rapid component swaps—transforming what was once a multi-hour maintenance task into a process that could be completed in minutes.

We also explored diamond-infused aluminum casting as a future path for even greater thermal conductivity—demonstrating our commitment to continuous innovation and material science.

The Result

From Digital Twin to Scaled Production — A Cross-Continental Success

With simulation insights and thermal strategies validated, we built a functional prototype using OEM-standard components and local supply chains in Ohio—leveraging circular economy principles to promote sustainability and material reuse.

Unlike many industry approaches that aim to build a perfect or near-perfect digital twin, our philosophy is different: we don’t treat the digital twin as the final answer, but as an accelerator and verifier of real-world development. This non-standard methodology allows us to move faster and validate more precisely, without getting bogged down in trying to simulate every physical nuance. Instead, we focus on using simulation to inform, test, and refine actual design iterations—creating a powerful feedback loop between virtual and physical engineering.

We conducted a full Design of Experiments (DoE) on the prototype, comparing real-world results to the digital twin created in the cloud during CFD modeling. The system not only met performance expectations—it exceeded them, thanks to the overhead built into both airflow management and modular integration.

The optimized placement of servers within the rack—ensuring minimal thermal interference between neighboring units—proved essential in maintaining cooling efficiency and consistent performance across workloads.

Following successful validation, we transitioned into small-run production by collaborating with the OEM's manufacturing partners in Shanghai. This included close work with local production engineers to finalize precision sheet metal fabrication and custom board assembly while preserving the thermal design integrity discovered through simulation.

This cross-continental effort produced a high-performance, high-density server system that:

Achieved thermal stability without relying on oversized fans or liquid cooling

Reduced energy consumption and improved Power Usage Effectiveness (PUE)

Enabled rapid servicing and future scalability via modularity

Supported long-term reliability by preventing thermal degradation

This project demonstrated how deep simulation, intelligent automation, and agile hardware design can come together to solve real-world problems—transforming a previously "unbuildable" concept into a production-ready, market-successful solution.