Case Study

Pioneering Water Sterilization Technology

Challenge

CUNY stands at the forefront of its field. Harnessing the power of pulsed UV-C radiation, this team revolutionized microbial inactivation in meat processing conveyor systems. With their expertise and cutting-edge approach, CUNY set a standard for effectiveness and efficiency in the industry.

Leveraging Detailed Design

CUNY's goal was ambitious yet clear: to leverage their UV-C radiation technology's power to transform how we approach water sterilization in order to provide a way to get water to people in crisis zones. A process previously restricted to bottled water and rationed based on the logistics of getting it into these areas. This inefficient process often does not provide people with the hydration they need and can be detrimental to the environment. However, as with any paradigm-shifting initiative, the road to success wasn't linear. Tio fundamental challenges stood in their way:

Lack of Desired Technology

The specific technology needed to embark on this groundbreaking endeavor would be a device that can fit in a car and clean and process water at a significant scale. Without the right tools to build on, transitioning the UV-C radiation technology to the water sterilization process posed an intricate challenge.

Absence of Horizontally Integrated Teams

A crucial element to the success of such an endeavor is the integration of various teams, working in unison towards a common objective. Yet, among CUNY's trusted partners, the necessary organization for such a horizontally unified front needed to be improved.

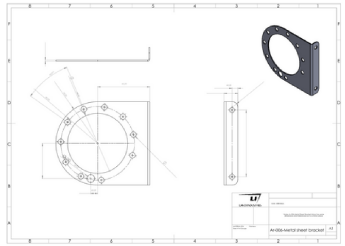

Metal Sheet Bracket Shop Drawing

Exploded View of Reactor

Services Rendered

Research and Development

User interviews (ie. comprehensive personas)

Process mapping (ie. end to end user journeys)

User-driven product requirements

Competitor product analysis

Design and Creation

Prototyping Software (low fidelity) (eg. Balsamiq)

Hand-drawn industrial designs

Photoshop renderings (ie. customer feedback)

Solidworks with PLM (ie. Complete rendering and creation)

Software Development

Platform Architecture (eg. AWS loT)

Application Development (eg. React, Python, Cognito)

Embedded Linux (eg. device operation)

Automated Testing and Build (eg. Github Actions)

Project Management

Modified Agile Hardware Design (MAHD)

JIRA CMMI for internal work tracking

Harvest Integration for project budgeting and oversight

Creating A Design of Experiments

Striving to tackle the industry's challenges head-on, Landi Industries allied with CUNY. United by common objectives, both organizations committed to collaborating to pursue solutions.

Examining Underlying Obstacles

Using a root cause analysis, they went further than addressing surface-level problems by interviewing water treatment facilities, pharmaceutical companies, and FDA compliance experts. This allowed for examining the deeper issues that restricted the development of current technological solutions.

Strategizing Integration

They embarked on a strategic thinking exercise recognizing the importance of seamless integration. Aimed to accurately anticipate, scrutinize, and understand the incorporation of the new device into already established systems.

Landi Industries applied a meticulous approach in their partnership, employing flow analysis, innovating designs, and identifying high-risk items. Utilizing off-the-shelf systems, Landi Industries guaranteed reliability by rigorously testing each component. Simultaneously, CUNY provided valuable insights and demonstrated adaptability, adjusting its technology to varying customer markets. Together, they highlight the critical role of customer insights in business strategies, further illustrating the rewards of collaboration, innovation, and commitment to excellence in engineering and manufacturing services.

The Result

In partnership with CUNY, Landi Industries developed an optimal solution in the form of a water sterilization system (pictured below). With a capacity to handle 60 GPM, it integrated seamlessly with existing water treatment facilities. Moreover, the system's design included an effective heat dissipation mechanism from the lamps, boosting reliability. The successful adaptation of UV-C radiation technology into water sterilization denotes a substantial leap forward in CUNY's' journey, showcasing the power of collaborative innovation.

Head Cap Mounting Detail

UV-C Lamp Wiring