Think Beyond the Function: Why Environmental Protection Should Be a Priority in Your Designs

When it comes to engineering and product development, ingress protection (IP) is often treated as a final checkbox—an afterthought added just before production. But if there's one lesson we’ve learned through building rugged, reliable systems, it’s this: ingress protection needs to be part of the conversation from day one.

What Is Ingress Protection, Really?

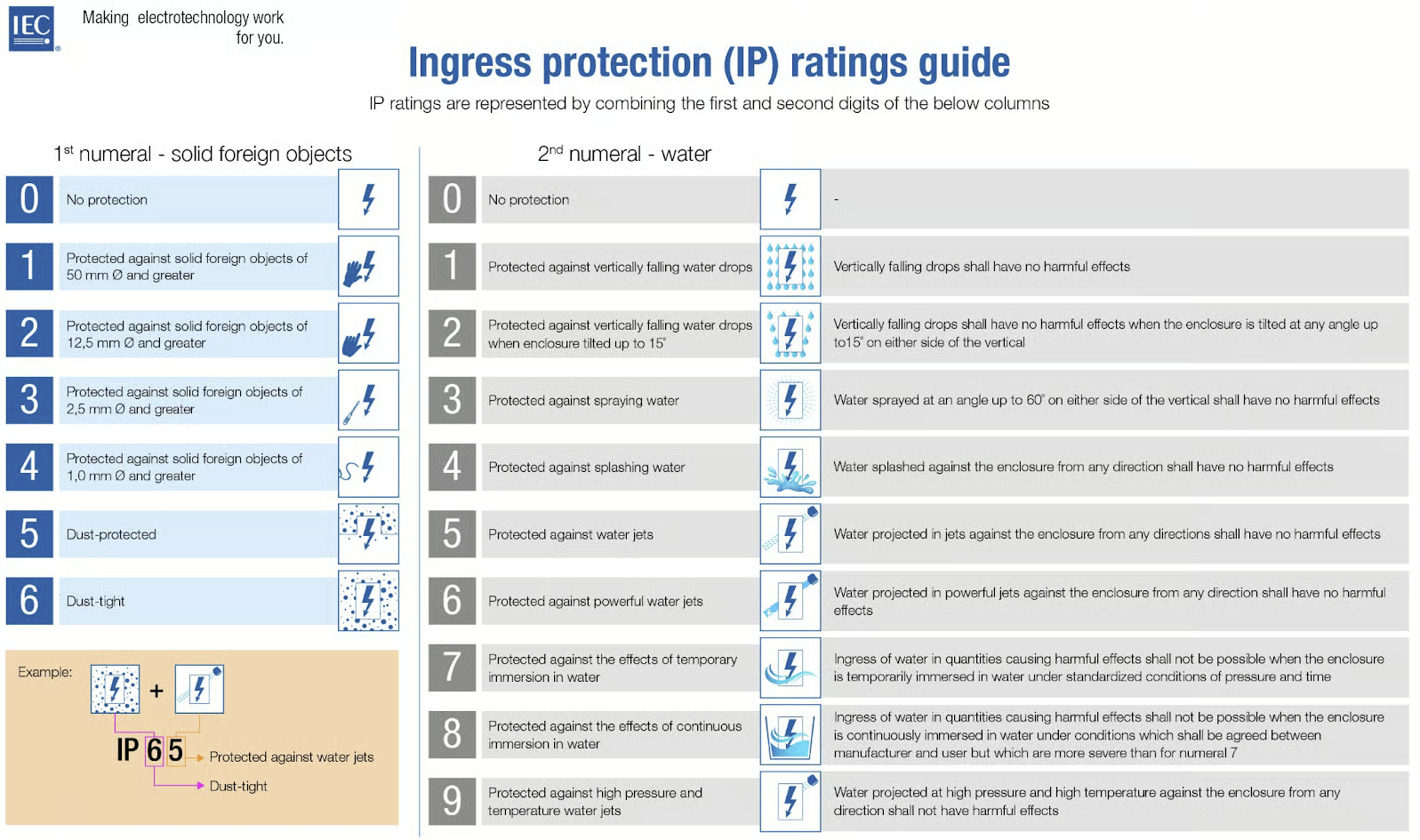

At its core, ingress protection refers to the measures used to prevent unwanted elements—such as dust, moisture, or liquids—from penetrating an enclosure. Whether you're developing a Programmable Logic Controller (PLC) panel for a factory floor or designing an outdoor electronic enclosure, an IP rating (e.g., IP54, IP65, IP68) defines how well your product will stand up to its environment.

These ratings are defined by IEC 60529, an international standard published by the International Electrotechnical Commission (IEC), which classifies the degrees of protection provided by enclosures for electrical equipment. The IP rating consists of two digits: the first refers to protection against solid objects (like dust), ranging from 0 (no protection) to 6 (dust-tight), and the second relates to protection from liquids, ranging from 0 (no protection) to 9 (high-pressure, high-temperature water jets).

For example, a factory-based device might need to be dust-tight (IP54), while an outdoor panel exposed to rain may require IP65 or IP67. High-performance systems, like those subject to pressure washing or immersion, may even target IP68.

Why It Needs to Be Discussed Early

Too often, IP requirements are retrofitted late in the design process—if they’re considered at all. But understanding the target IP rating early unlocks crucial insights about how your system will be used, what environmental challenges it faces, and how users will interact with it.

Consider an electronics carry case for use in a cement truck. Not only does it need to withstand hose-down cleaning, it must also survive intense vibration—comparable to rocket launch dynamics. These factors deeply influence everything from enclosure mounting methods to gasket selection and sealing techniques.

As engineers, we’re faced with multiple ways to achieve a desired rating like IP68. We might:

Use internal sonic welding for seamless sealing

Design screw mounts that are externally sealed with overlaid silicone

Employ multi-barrier sealing systems with gaskets, compression mechanics, and physical walls to prevent seepage even after gasket failure

It’s also worth noting that certain ratings are not cumulative. For instance, IP68 (continuous immersion) does not necessarily imply resistance to high-pressure water jets, which falls under IP69 or IP69K. Understanding these distinctions—directly from IEC 60529—prevents overconfidence in a rating that may not cover all environmental threats.

The earlier you identify your ingress protection goals, the better equipped your team will be to design with confidence and clarity.

How IP Influences Prototyping and Proof of Concept

While IP may not be required for early-stage prototypes or minimum functional products, incorporating IP thinking into your proof-of-concept (POC) pays dividends. For instance, selecting the right battery configuration for a device going into an autoclave (high heat, pressure, sterilization) differs vastly from one designed for use on a weather balloon (low pressure, extreme temperatures, etc.).

Even when physical sealing isn’t built into your early prototypes, knowing what’s coming helps engineers plan for form factor limitations, environmental loads, and test scenarios later on.

Design of Experiments (DOEs) and IP Testing

Designing for ingress protection also impacts your Design of Experiments (DOE). Understanding the different sealing strategies—whether via gasket compression, welds, or molded barriers—can guide your DOE phases, helping your team:

Validate multiple sealing methods

Simulate user interactions under real-world stressors

Systematically escalate tests from basic to aggressive environmental simulations

For clarity: gaskets and grommets are not created equal. Gaskets, like engine head gaskets, are compressible, torque-specific components used for tight, durable seals. Grommets, by contrast, are often softer and more flexible—ideal for user-access panels or cable interfaces.

We’ll be diving into the differences between gasket types, materials, and use cases in an upcoming article.

Conclusion: Build for the Environment, Not Just the Function

Ingress protection isn’t just about checking a spec sheet box. It’s about building systems that endure their environments and serve users reliably over time. By grounding your design process in IEC 60529 from the outset, and understanding what each level of IP rating really entails, you equip your team to make smarter decisions early—and avoid costly surprises later.

Start your IP discussions early, build it into your design and testing workflow, and you’ll avoid costly redesigns while shipping more robust products.

Stay tuned for more deep dives on engineering fundamentals—from gasket materials to vibration testing strategies.