Engineering Differently: The Landi Approach to ROI-Driven Product Development

Over the past decade at Landi Industries, we’ve discovered that we don’t just build products—we build them differently. That difference didn’t happen overnight. It stems from years of fixing broken projects, understanding where they go wrong, and learning how to align engineering with real business outcomes.

Before founding Landi, my job was to step into troubled projects and turn them around. Initially, I assumed these failures were due to miscommunication, disjointed contractors, or complex technical issues. But with time, it became clear: the real problem usually wasn’t technical at all. It was the lack of integration between engineering and business strategy—particularly a lack of clarity around ROI.

ROI Is the Real Project Killer

Most projects don't fail because the engineering team made a mistake. In fact, true technical failures are rare. What derails projects is a lack of clear expectations around Return on Investment(ROI): a poor understanding of how the product will generate value for the business, how the research supports sales, and what outcomes stakeholders expect.

This is especially true in both startups and large corporations, where there’s often a disconnect between development goals and business goals. When teams aren’t aligned around ROI from the start, even technically successful products can fall short.

Rethinking the Project Model

At Landi, we take a different approach—one inspired not by traditional engineering contracts, but by the film industry.

We use what we call a “studio model”. Like developing a movie, we begin with the plot, then move to the acts, and finally, we script the individual scenes. This phased approach gives our clients creative flexibility while also providing engineers with the structure and constraints needed to succeed.

Too often in product development, engineers are left to “ad-lib” solutions on the fly. While creativity is important, too much improvisation leads to misalignment, scope creep, or worse—product failure. Our model balances freedom and discipline to maximize alignment and impact.

“Phase 1”: Understanding the Problem

Our first phase focuses entirely on discovery. We work closely with clients to understand the problem, the user, and the environment the product or machine will operate in.

Whether we’re helping a medical device company upgrade legacy equipment or working with a major automaker to modernize a machine from the 1960s, this phase is about clarity. We assess:

Who is using the product or machine?

How are they using it?

What environmental or ergonomic factors are at play?

What regulatory burdens (like OSHA) need to be addressed?

This phase often includes on-site walkthroughs and time trials. These aren’t just casual observations—we’re gathering data to ensure our solution improves efficiency, safety, and business outcomes.

Design of Experiments (DOE): Bridging Engineering and Business

What sets our model apart is how we integrate Design of Experiments (DOE) into both engineering and business goals. We don’t just test to see if the system works—we validate whether it supports the ROI targets that matter to stakeholders.

In startups, we often map our DOEs to investor-defined tranches—milestones that trigger funding releases. In corporations, it’s strategic alignment to cost-reduction, market entry, or key performance indicators (KPI)s. Either way, we treat these checkpoints as critical indicators of success, not just for the engineering but for the project as a whole.

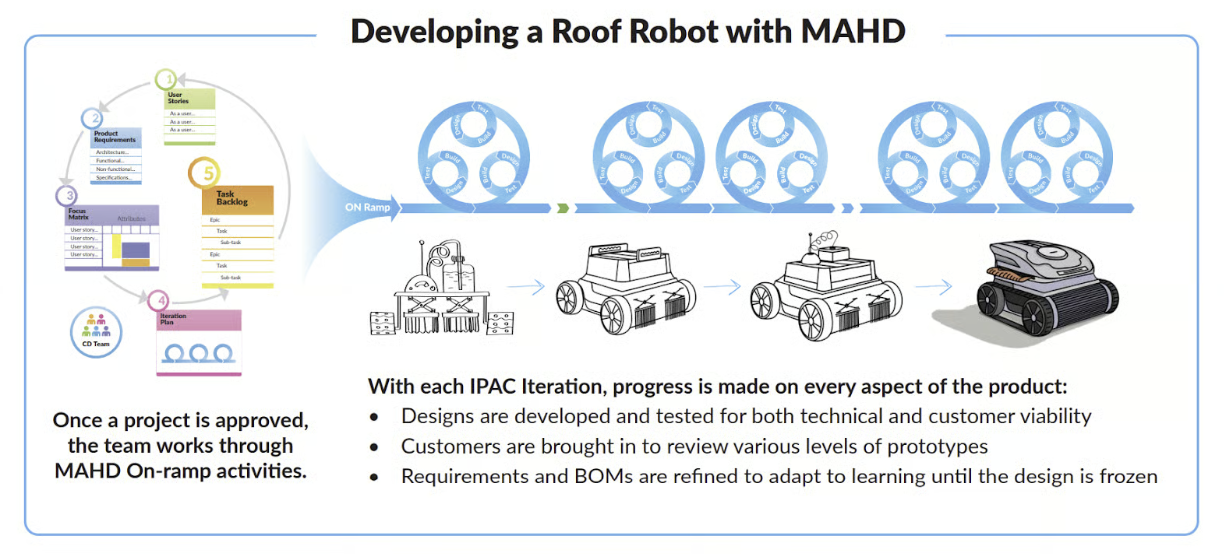

MAHD: Modified Agile Hardware Design

We operate using a Modified Agile Hardware Design (MAHD) methodology. Unlike traditional hardware development, which often drags out over months or years without feedback, our approach emphasizes iteration and transparency.

Clients work with us in short cycles—typically one-month sprints—where we meet weekly (or more) to review progress, refine scope, and adapt as needed. This cadence ensures everyone stays aligned, budgets are respected, and surprises are minimized.

MAD gives engineers a rhythm. It gives clients confidence. Most importantly, it ensures that the project doesn’t just “work”—it works for the business.

Hitting Goals, Not Just Milestones

It’s not enough to build something that functions. If the final product doesn’t meet ROI goals—like hitting a target cost, enabling automation, or eliminating a regulatory burden—it can still be a failure.

We’ve seen it many times: a technically brilliant solution that’s too expensive to scale, or a clever mechanism that solves one problem but creates another. That’s why our front-end process is so focused on setting the right objectives early—so the entire team is rowing in the same direction.

Conclusion: Engineering for Outcomes, Not Just Output

At Landi Industries, we don’t just engineer solutions—we engineer outcomes. By aligning engineering processes with business goals, validating them through rigorous experimentation, and structuring work in agile, manageable phases, we help our clients reduce risk, save money, and actually deliver.

Because in the end, great engineering isn't about invention alone—it's about integration.