Ensuring Durability and Compliance: Anodization Insights for Medical Device Makers

In the realm of medical device manufacturing, surface finishing is a critical step, especially when working with metals. Among the metals frequently employed, stainless steel is popular due to its strength and corrosion resistance. However, its cost and poor thermal conductivity often make it unsuitable for thermally sensitive applications. Titanium, while commonly used in implantable devices due to its biocompatibility and anodization capability, is not ideal for components requiring efficient heat dissipation. This is where aluminum, particularly from the 6000 series, becomes a valuable alternative due to its excellent thermal conductivity and relatively lower cost.

Despite its advantages, aluminum presents challenges in durability—prone to scratching and denting—and must be adequately finished to prevent degradation during sterilization. The two most common sterilization methods—vaporized hydrogen peroxide (VHPS) and autoclaving—impose constraints on the types of surface treatments and finishes that can be used. VHPS, in particular, poses challenges for anodized aluminum, primarily due to color fading or bleaching, especially when inorganic dyes are involved.

Understanding Anodization

Anodization of aluminum is an electrochemical process that enhances surface hardness and corrosion resistance. However, it is essential to prepare the surface properly before anodizing. Surface treatments often involve aluminum oxide blasting (typically 80 to 120 grit), which helps to mask machining marks that would otherwise be accentuated after anodization. Sandblasting is discouraged due to its inconsistency and potential aggressiveness.

Types of Anodization: Class I vs. Class II

There are two primary classes of anodization relevant to medical applications:

Class I Anodization: This method allows for a wide range of vibrant colors using organic or inorganic dyes. However, inorganic dyes are susceptible to degradation under sterilization—particularly VHPS—due to dye leaching from the porous oxide layer. Even when sealed with a clear coat, fading is inevitable.

Class II Anodization: This process typically avoids coloring and results in a darker, natural gray or black finish due to longer immersion times, which produce thicker oxide layers. Although some coloration can be added, the results are more subdued than Class I, and any dye used (especially inorganic) may still fade under sterilization.

The Role of MIL-SPEC in Anodization

Military Specifications (MIL-SPEC), such as MIL-A-8625, provide standardized requirements for anodization requirements for anodizing aluminum alloys used in demanding applications. These specifications guide critical parameters such as oxide thickness, corrosion resistance, sealing methods, and wear durability, which are crucial in both defense and high-reliability medical contexts. These include:

Type I (Chromic Acid),

Type II (Sulfuric Acid),

Type III (Hardcoat Anodize).

These MIL-SPECs are rooted in applications where durability under extreme environments—temperature, abrasion, chemical exposure—is essential. While originally designed for aerospace and defense, the standards have direct relevance in medical device applications, particularly where ruggedized or field-deployable units are required.

These specs also differentiate between Class 1 (non-dyed) and Class 2 (dyed) finishes. While MIL-SPEC provides a framework for quality, it does not inherently ensure compatibility with medical sterilization cycles. Therefore, choosing the appropriate specification and validating performance in sterilization scenarios is critical.

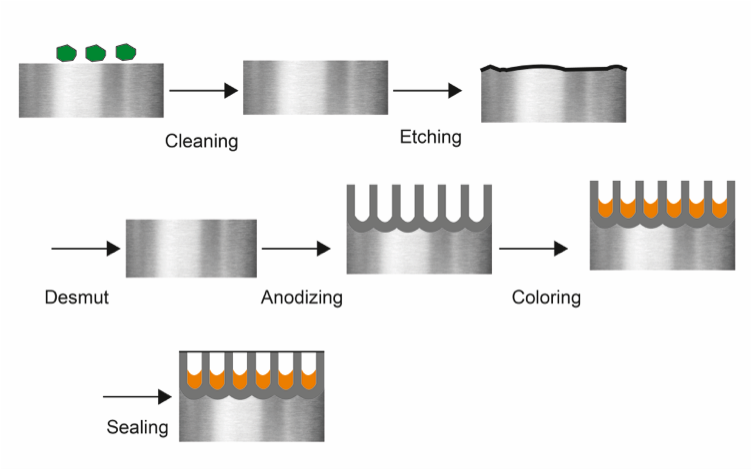

Anodization Process Steps

The anodization process is a controlled electrochemical procedure designed to enhance the durability, corrosion resistance, and (if desired) aesthetics of aluminum parts. Below are the typical steps involved, along with key chemical considerations:

1. Cleaning (Degreasing & Deoxidizing)

Purpose: Remove machining oils, fingerprints, and oxides. Common Chemicals:

Alkaline degreasers (e.g., sodium metasilicate or caustic soda-based solutions)

Acid deoxidizers (e.g., nitric acid or chromic acid mixtures to strip oxides)

2. Etching / Surface Preparation

Purpose: Uniform surface texture, aesthetic prep, and minor defect removal. Common Chemicals:

Sodium hydroxide (NaOH)

Desmut solutions (e.g., nitric acid or ferric nitrate)

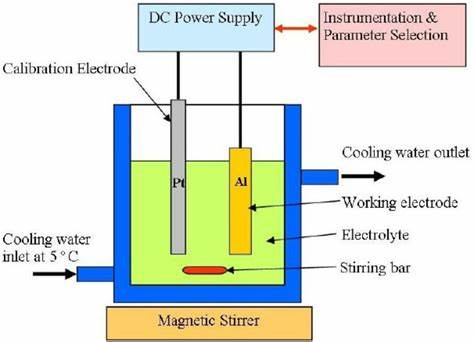

3. Anodizing (Electrolytic Oxide Formation)

Purpose: Form a porous aluminum oxide layer. Common Electrolytes:

Sulfuric acid (Type II)

Chromic acid (Type I)

Sulfuric acid under higher voltage and cooling (Type III)

4. Dyeing (Optional)

Purpose: Add color. Dye Types:

Organic dyes

Inorganic dyes

5. Sealing

Purpose: Close the oxide pores and lock in dye. Common Methods:

Hot deionized water sealing

Nickel acetate sealing

Chromate sealing

Important Note: If laser etching (for part numbers, logos, UDI codes, etc.) is part of your process, it is recommended to perform laser etching prior to sealing. This ensures better contrast and avoids microcracking or chipping of the sealed oxide layer. Sealing after laser marking can also help protect the etched surface and improve long-term durability, especially in medical or high-cleanliness environments.

Questions to Ask Anodizers When Selecting for Your Product

Process Capability & Control

What anodizing types do you offer? Are you MIL-A-8625 certified?

How do you ensure the chemical solution and coating thickness stay accurate and consistent during anodizing?

Material Compatibility

Have you worked with anodizing specific types of aluminum, like 6061 or 7075, which are often used in high-performance parts?

How do you handle mixed-metal parts?

Dye & Seal Performance

What dyes are used, and how stable are they post-sterilization?

What sealing method is used, and is it compatible with VHPS/autoclave?

Medical Readiness

Do you serve medical clients regularly?

Are Class II non-colored finishes supported?

Quality & Development

Do you have certifications like ISO 9001 for manufacturing quality, or ISO 13485, which is specifically for making medical devices??

Are you open to working with us on design of experiments (DOEs) or validation testing to help us understand how different process settings affect quality and ensure consistent results?

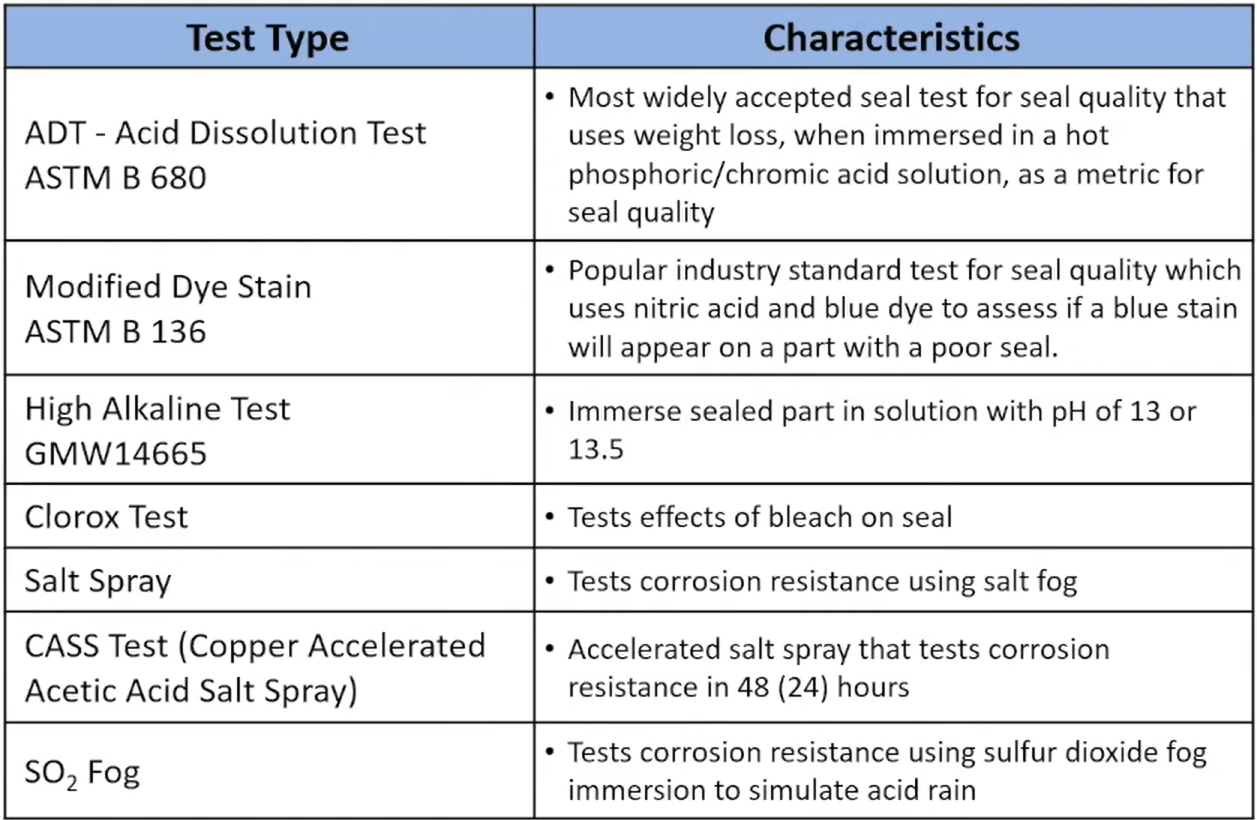

Testing and Validation: Ensuring Repeatable Results

Even when anodizing is outsourced, internal validation is essential. Without controlled chemistry and thorough verification, product development risks include invalid DoEs, misleading test data, and failed process qualifications.

Common Validation Methods:

This level of oversight is vital for accurate process mapping, PFMEAs, and production readiness.

Best Practices and Recommendations

Use Class II anodization with no coloring for VHPS/autoclave compatibility.

If color is needed, use Class I with chromium finish and seal, but test extensively.

Always validate parts—regardless of vendor experience.

Embed anodizing knowledge into early-phase DoEs and process control documents.

Conclusion

Anodization is more than a surface treatment; it is a critical-to-function process requiring strict chemistry control, testing, and documentation. Engaging with experienced anodizing partners, validating each step, and integrating this knowledge into your development and manufacturing plans ensures long-term product success in regulated environments. Working with incorrect manufacturers, however, can lead to a misdiagnosis of needs, resulting in improperly specified processes that can compromise product quality, performance, and compliance. In the end, this can lead to significant regulatory hurdles, brand damage, and costly setbacks that could have been avoided with a more careful, informed approach.

Interested in Learning More?

If you're looking to dive deeper into risk management, software lifecycle standards, or reprocessing requirements, feel free to reach out. Whether you need templates, training courses, or consulting, there are numerous resources available to help streamline your medical device development and regulatory processes.

Let’s work together to make the regulatory journey simpler and more efficient! 🌐 Website

Or stay connected with us on our social platforms for updates, resources, and more: