Landi Industries

Established 2016

Let’s Talk hello@landiindustries.com

12M+

Lines of Code

65+

Projects Delivered

12

Industry Verticals

8+

Patents

We deliver projects that matter

focusing on customer driven value

We side step the common trap of lumping all the work into a “large” MVP and instead focus on the journey with our customers; first starting with proofing concepts and then demonstarting value of those components to business ROI.

Technical Capabilities

MECHANICAL ENGINEERING

- End to End Industrial Design

- Design For Manufacturing (DFM)

- Modeling, Simulation, DOE

- Rapid Prototyping

- Tooling Design

- Reverse Engineering

ELECTRICAL ENGINEERING

- Schematic/Board Design & Layout

- High-Speed Circuit Design

- Field-Programmable Gate Array (FPGA)

- Digital Signal Processing (DSP)

- Component Procurement/BOM Generation

- PCB Fab, Testing, and Assembly

FIRMWARE

SOFTWARE

- RTOS, Embedded Linux, Zephyr

- C, C++, Python, Rust

- CANBus, ModBus, I2C, SPI, UART

- Queue Driven State Machines

- Event-Driven Firmware.

- Internet of Things (IoT) and IIOT

- Cloud setup/mgmt (Azure, AWS, Ansible, K8s)

- Web interface (Python, Javascript, React)

- Mobile Dev (ie. Go, React Native, C#)

- SaaS Development (User Mgmt, Payments)

- AI/ML and Vision Inspection Systems

- Web3 and Blockchain

We’ve Walked in Your Shoes,

Let’s Talk Shop

Horizontally Aligned

Landi has built our team around the ability to take ideas from their infancy to retail-ready products. With teams across multiple design and engineering disciplines, we’ve cutout the barriers between practices; improving communication and streamlining the process.

- Product Market Fit Exploration

- Product Discovery + Research

- Holistic Product Development

- Individual Engineering Practices

- Human Factors Engineering + Usability Studies

- Team Enhanced Talent Offset

How We Get Sh*t Done

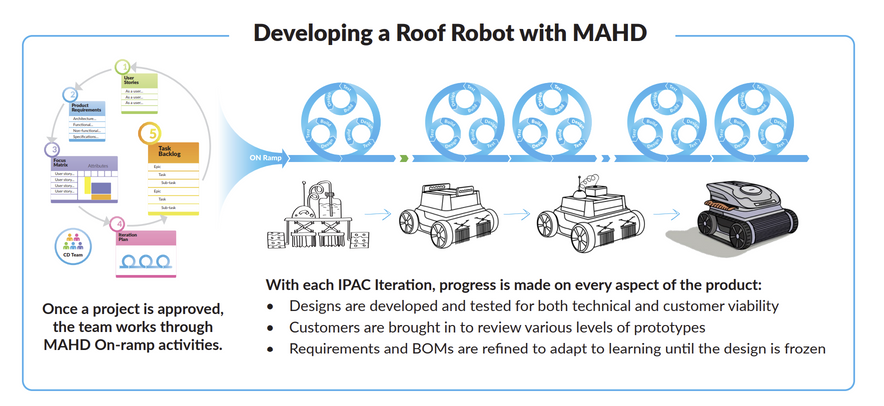

Our implementation of the Modified Agile for Hardware Development (MAHD) Framework uses the principles of AGile to develop physical products in less time, with reduced risk, and with higher customer satisfaction with (normally) weekly deliverables for customer review.

Partner Network:

Copyright © 2024 LANDI INDUSTRIES. All Rights Reserved.